Electrical Maintenance Checklist

An effective electrical maintenance checklist guarantees your system’s safety and efficiency. Start with a visual inspection of components for overheating, frayed wires, and corrosion. Test circuit breakers by toggling them and check fuses for damage. Inspect outlets and switches for functionality, guaranteeing GFCI outlets work correctly. Next, assess wiring for cracks and connection integrity. Document your findings thoroughly to maintain compliance and track repairs. To stay updated, explore more essentials of electrical maintenance.

Key Takeaways

- Conduct regular visual inspections for overheating, frayed wires, and damaged circuit breakers to ensure safety and compliance.

- Test circuit breakers and fuses periodically to verify functionality and prevent electrical failures.

- Inspect outlets and switches for damage, ensuring GFCI outlets are functioning correctly.

- Check wiring and connections for integrity, looking for fraying and corrosion to maintain safety.

- Document inspections and repairs to maintain compliance and track the electrical system’s condition.

Importance of Regular Electrical Maintenance

Regular electrical maintenance is essential not only for guaranteeing safety but also for prolonging the lifespan of your electrical systems. By adhering to a systematic maintenance schedule, you can enhance safety compliance, mitigating risks associated with electrical failures.

Routine checks help identify potential hazards such as frayed wires or overloaded circuits, which can lead to dangerous situations.

Additionally, regular maintenance boosts energy efficiency. Well-maintained electrical systems operate with peak performance, reducing energy consumption and lowering utility bills.

Keeping components clean and functional prevents waste and enhances overall system reliability. You should prioritize these tasks to guarantee both safety and efficiency, safeguarding your property while maximizing the operational lifespan of your electrical infrastructure.

Regular maintenance isn’t just a recommendation; it’s a necessity.

Visual Inspection of Electrical Components

Although electrical systems are often taken for granted, a thorough visual inspection of their components is essential for identifying potential issues before they escalate.

Regular inspections help you spot safety hazards and monitor component wear, guaranteeing your system operates effectively.

Here are key aspects to focus on during your inspection:

- Look for signs of overheating around connections or components.

- Check for frayed or damaged wiring that could pose a risk.

- Inspect circuit breakers for any physical damage or discoloration.

- Observe for signs of corrosion on terminals or connectors.

- Ascertain that all covers and enclosures are properly secured and intact.

Testing Circuit Breakers and Fuses

Testing circuit breakers and fuses is essential for ensuring the reliability and safety of your electrical system.

Start by checking circuit breaker functionality; flip each breaker to the off position and then back on, observing if it trips immediately or remains stable. If a breaker trips repeatedly, it may indicate an overload or a fault in the circuit.

For fuses, remove each one and inspect for visible damage or a blown element. If a fuse is faulty, follow proper fuse replacement procedures: turn off power, remove the old fuse, and install a new one of the same rating.

Regular testing can help prevent electrical failures and hazards, ensuring your system operates smoothly and safely.

Checking Outlets and Switches

To guarantee your electrical system operates safely, checking outlets and switches is essential. Begin by inspecting each outlet for any signs of damage or discoloration, which can indicate a serious issue. Test switch functionality by toggling them on and off, confirming they respond correctly.

- Look for loose outlets that can cause sparks.

- Ascertain GFCI outlets are functioning by pressing the test button.

- Verify that all switches are securely mounted and not wobbly.

- Check for any burning smells or unusual heat from outlets.

- Replace any non-working outlets or switches immediately for outlet safety.

Regularly maintaining these components helps prevent electrical hazards and confirms your system works efficiently.

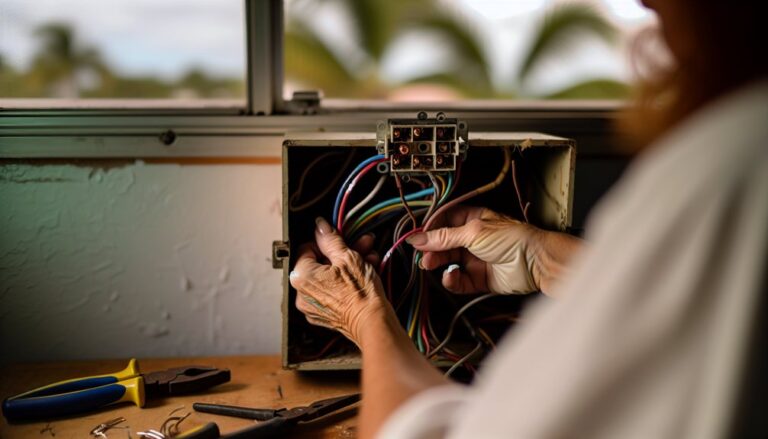

Inspecting Wiring and Connections

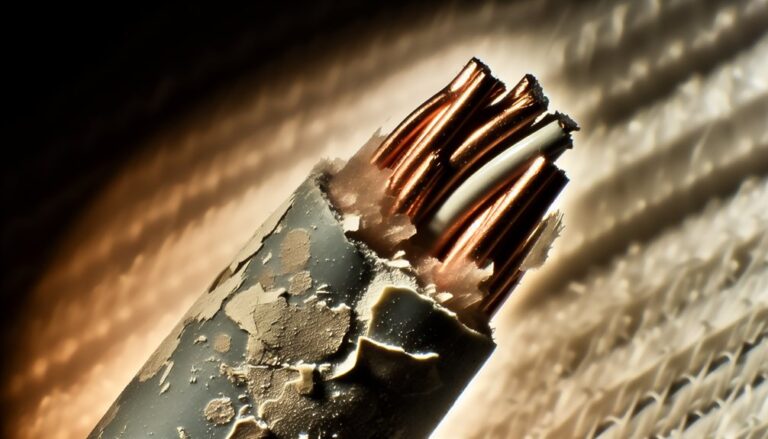

When you inspect wiring and connections, it is crucial to look for any signs of wear or damage that could compromise safety. Start by checking the wire insulation for cracks or fraying. Damaged insulation can lead to short circuits or electrical fires. Next, assess the connection integrity; loose or corroded connections can result in arcing, which poses serious risks.

| Issue | Consequence | Action Needed |

|---|---|---|

| Frayed wire insulation | Short circuit potential | Replace damaged wires |

| Loose connections | Arcing and overheating | Tighten or replace terminals |

| Corroded connections | Power loss and fire risk | Clean or replace connectors |

| Overheating wires | Insulation damage | Reduce load or upgrade wires |

| Inconsistent voltage | Appliance malfunction | Check connections and wiring |

Evaluating Electrical Appliances

After ensuring that wiring and connections are in good condition, the next step involves evaluating electrical appliances to confirm their operational safety and efficiency.

Appraising energy efficiency can greatly impact your overall energy consumption and costs. Regular checks can also extend the appliance lifespan, reducing the need for premature replacements.

- Inspect power cords for fraying or damage.

- Test appliances for unusual noises or odors.

- Verify that appliances are properly grounded.

- Check energy ratings and compare them to newer models.

- Clean filters and vents to maintain airflow.

Documenting Maintenance Findings and Actions

While evaluating electrical appliances, it’s crucial to document your maintenance findings and actions systematically.

Maintain detailed maintenance logs that chronicle each inspection, noting any irregularities or concerns. These logs should include dates, equipment identifiers, and specific observations to promote clarity and traceability.

After addressing any issues, create action reports that summarize the steps taken to resolve them. Include the nature of the repairs, replacement parts used, and any follow-up actions required.

This documentation not only serves as a historical record but also aids in compliance with safety regulations.

About Us

We understand that electrical issues can be stressful and overwhelming. That’s why we are here to lend a helping hand and provide you with the best electrical services in town. As a team of experienced electricians, we take pride in our ability to solve any electrical problem with precision and care.

Pages

Follow us

© 2026 By Electrician Fort Lauderdale Today