Handling Electrical Equipment Malfunctions

When handling electrical equipment malfunctions, you must take a systematic approach. Start by identifying issues like circuit overloads or faulty wiring. Always guarantee safety protocols are followed; turn off power and use insulated tools to prevent shocks. If you notice frequent breaker trips or unusual odors, it’s time to call a professional. Regular inspections and maintenance can prevent many issues. There’s more you can do to guarantee safety and efficiency in your approach to electrical equipment.

Key Takeaways

- Regularly inspect electrical equipment to identify potential issues before they escalate, focusing on connections and signs of wear.

- Use diagnostic tools to effectively troubleshoot malfunctions and isolate problems systematically.

- If circuit breakers frequently trip or lights flicker, consider contacting a professional electrician for safe diagnosis and repair.

- Always ensure power is turned off and use insulated tools when handling electrical components to eliminate shock hazards.

- Document inspections and maintenance to track performance trends and schedule proactive replacements of worn parts.

Common Electrical Equipment Issues

When dealing with electrical equipment, it’s important to recognize common issues that can arise, as these problems often lead to inefficient performance or complete malfunction.

One prevalent issue is circuit overloads, which occur when too many devices draw power from a single circuit, exceeding its capacity. This can cause breakers to trip, leading to downtime and potential damage to equipment.

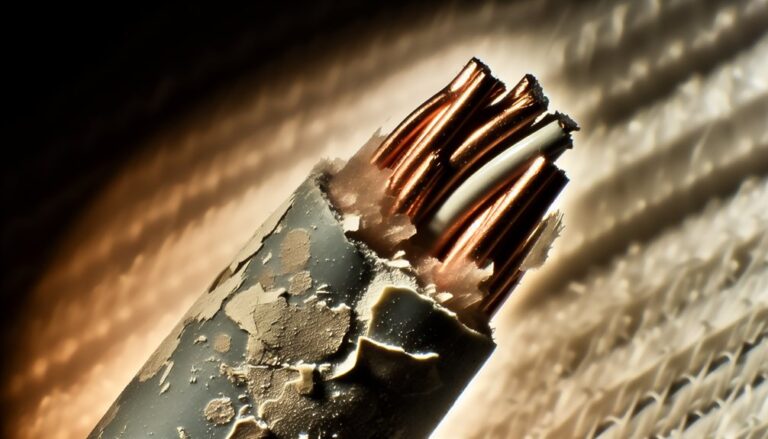

Another significant concern is faulty wiring, which can result from wear, improper installation, or environmental factors. Faulty wiring can lead to short circuits, sparking, or even fires, posing serious safety risks.

Regular inspections can help identify these issues before they escalate, ensuring your electrical systems operate safely and efficiently. Prioritizing these checks can save you time and resources in the long run.

Troubleshooting Techniques

How can you effectively troubleshoot electrical equipment malfunctions? Start by using diagnostic tools to identify the issue. Perform isolation procedures to guarantee safety and prevent further damage. Follow a systematic approach:

| Step | Action | Tools Required |

|---|---|---|

| 1. Identify | Observe symptoms | Multimeter, Visual Inspection |

| 2. Isolate | Disconnect power sources | Circuit Breaker, Switches |

| 3. Diagnose | Test components | Oscilloscope, Clamp Meter |

| 4. Repair | Replace or fix parts | Screwdrivers, Soldering Iron |

When to Call a Professional

Recognizing the right moment to call a professional can save time and prevent further complications in electrical equipment malfunctions.

If you notice signs of malfunction—like frequent tripping of circuit breakers, flickering lights, or unusual odors—it’s vital to act promptly. These symptoms may indicate underlying issues that could escalate into serious electrical hazards if left unaddressed.

Additionally, if you’re unsure about the nature of the problem or lack the necessary tools and expertise, don’t hesitate to contact an electrician. They possess the skills to diagnose and resolve complex issues safely.

Safety Precautions to Consider

Addressing electrical equipment malfunctions requires not only prompt action but also a commitment to safety.

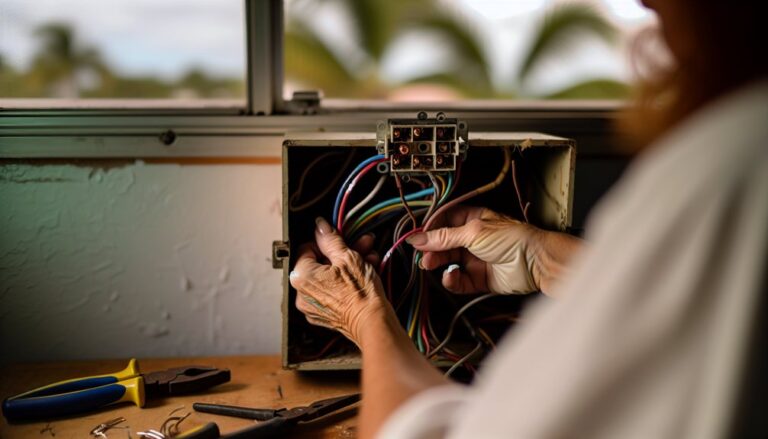

Before you proceed, always verify the power is turned off to eliminate shock hazards. Inspect for any signs of circuit overloads, such as burning smells or tripped breakers. Use insulated tools to minimize risk when handling electrical components.

Keep your workspace dry and free of clutter to prevent accidental contact with live circuits. If you’re unsure, avoid attempting repairs and consult a qualified technician.

Wear appropriate personal protective equipment, including gloves and safety goggles, to safeguard against unexpected incidents.

Preventative Maintenance Tips

While regular inspections and maintenance may seem time-consuming, implementing a preventative maintenance schedule is essential for extending the lifespan of your electrical equipment.

Start by conducting thorough preventative inspections, which should include checking connections, identifying wear, and ensuring components are functioning correctly. Schedule routine checks on a monthly or quarterly basis, depending on usage and equipment type. Document each inspection to track performance trends and issues over time.

Additionally, replace worn parts proactively to avoid unexpected failures. Educate your staff on recognizing early warning signs, such as unusual sounds or heat.

About Us

We understand that electrical issues can be stressful and overwhelming. That’s why we are here to lend a helping hand and provide you with the best electrical services in town. As a team of experienced electricians, we take pride in our ability to solve any electrical problem with precision and care.

Pages

Follow us

© 2026 By Electrician Fort Lauderdale Today